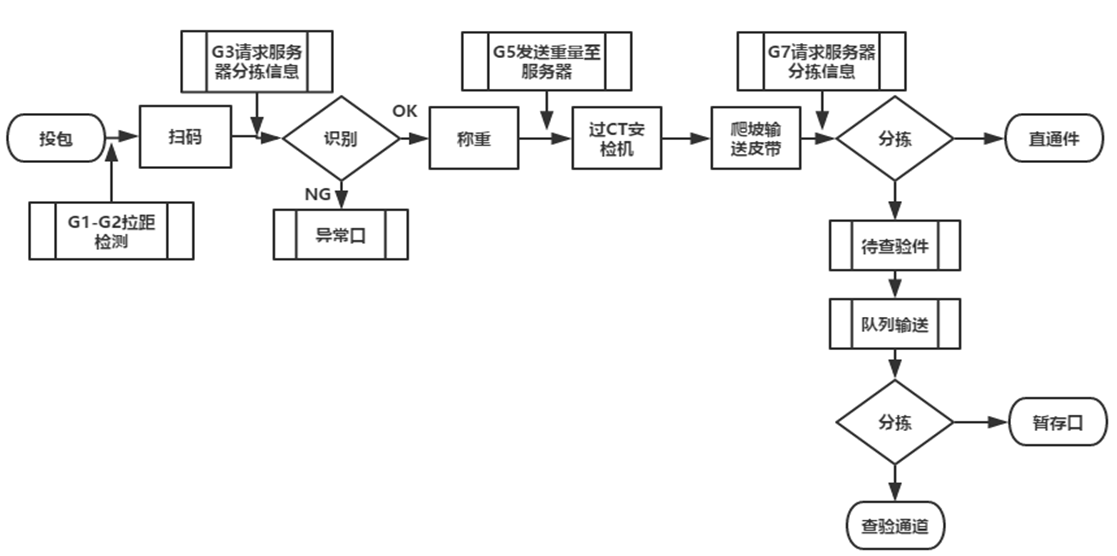

Work flow:

(1) the system detects whether the whole system equipment is started and ready;

(2) read the package bar code, check the cargo information, and fail to read the abnormal port;

(3) the test results and weighing information of the package X-ray (CT) are transmitted to the real-time database and retained;

(4) matching the real-time data collected on the parcel site with the historical data declared by EDI of the parcel;

(5) receiving sorting port address and issuing control instructions and data storage according to processing information.

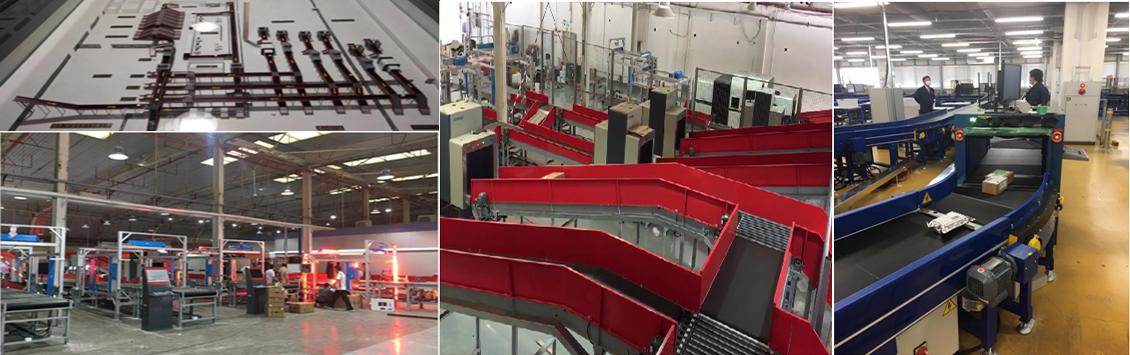

Project configuration:

Main sorting lines: 4;

Number of balance wheel units: 16 groups;

Sorting efficiency: ≥7000 pieces/hour (medium and large pieces);

Size range: MAX. 1000L×600W×500H, 40kg; MIN. 400L×250W×300H, 10kg.